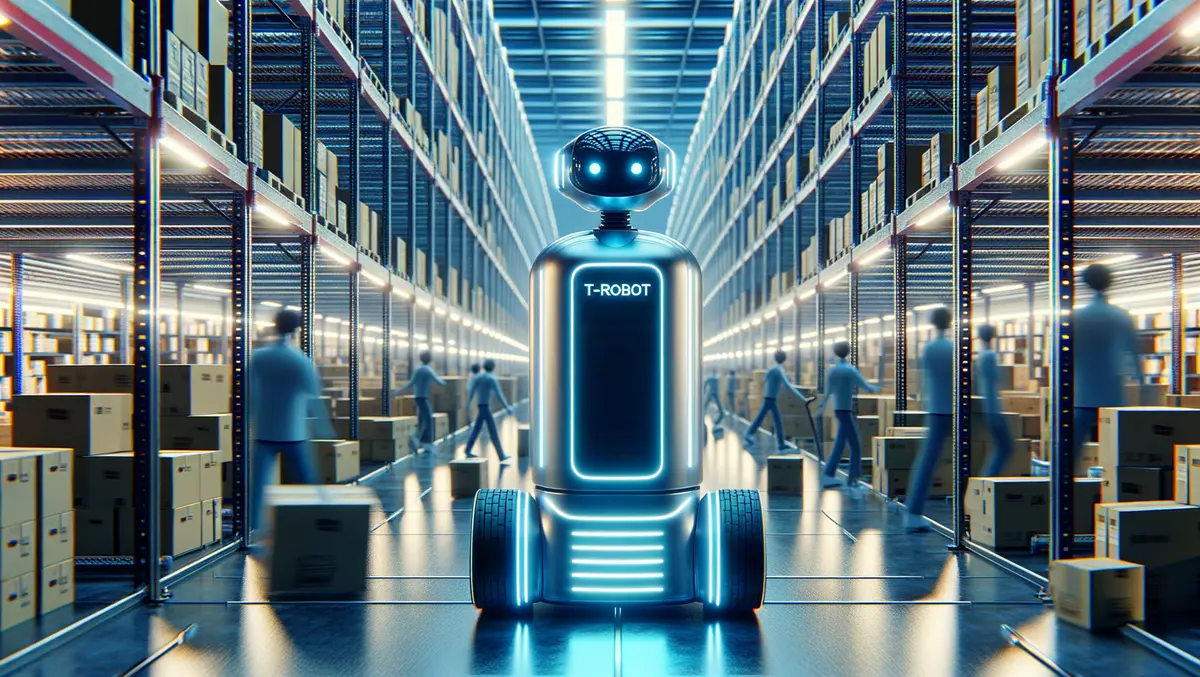

AutoStore fosters Japanese warehouse efficiency with T-Robot solution

Warehouse efficiency in Japan takes a step forward as AutoStore collaborates with Taisei Corporation and Toyo Kanetsu K.K. to create a revolutionary 'T-Robot Storage Production solution.' This solution facilitates the optimisation of warehouse operations amid an increasing demand for advanced and efficient automation solutions.

As a technology company specialising in automated warehouse solutions, AutoStore has supported its Japanese partners in the development and launch of the T-Robot storage production solution for manufacturing settings. The solution, hosted in Tokyo, is designed around AutoStore's standardised modular product design. This allows partners to tailor solutions to customer-specific needs and gives rise to a variety of warehouse configurations.

The new system utilises AutoStore's proven efficient automated storage technology within a three-dimensional grid. Robots equipped with advanced picking functions navigate along tracks built above the grid, ensuring the direct transportation of assembled parts to different production stations. As such, this system is designed to directly support just-in-time manufacturing processes by reducing intermediate handling steps and ensuring continuous production flows.

The T-Robot Storage Production System has several key features. Firstly, it enhances material handling. The system features robotic technology that moves materials straight from storage to production stations, thereby streamlining workflows and minimising handling time. Second, space maximisation is achieved through AutoStore's compact grid. This aspect ensures optimal vertical and horizontal space usage within the manufacturing facilities. Lastly, the system stresses flexibility and scalability. This means the system's design can be tailored and scaled according to the events of modern manufacturing environments, helping businesses stay adaptable in a changing landscape.

Furthermore, the system's focus on space savings and automation reduces the physical footprint of storage areas and manual labour in material transport. Sub-storages strategically placed above each process area ensure prompt material supply, streamlining production and improving efficiency.

The collaboration between AutoStore, Taisei Corporation, and Toyo Kanetsu K.K. marks a significant technological advancement in warehouse efficiency in Japan with the introduction of the T-Robot Storage Production solution. By leveraging AutoStore's unparalleled expertise in automated warehouse solutions, this innovative system optimises warehouse operations and revolutionises material handling and production processes.

With its emphasis on enhancing workflows, optimising spatial utilisation, and ensuring adaptability and scalability, the T-Robot Storage Production System marks a significant advancement in addressing the needs of contemporary manufacturing environments. As Japan increasingly adopts cutting-edge automation solutions, this partnership establishes a groundbreaking benchmark for efficiency and productivity, reshaping the realm of warehouse management practices in the country.